What do factories prioritize most? What do they need?? The answer is to focus on monitoring and managing manufacturing processes, employees, quality control, the product lifecycle, inventory, and all aspects related to the manufacturing department. Due to the significant global advancements in the manufacturing sector, businesses are turning to new Enterprise Resource Planning (ERP) systems to improve production processes, enhance efficiency, and streamline administrative operations. One of these solutions is the Odoo ERP system to track and monitor the product lifecycle, starting from its purchase as raw material until it reaches the final product and is shipped to your customers.

First: Odoo's management of factories and the integration of the manufacturing app with business requirements.

Odoo modules have been allocated for managing manufacturing stages and operational details for each stage.

Odoo also provides integrated modules for quality management, warehouses, shipping and supply chains, purchase orders, and supplier chains. IT provides integrated quality management modules that allow for the identification of inspection points, automatic creation of quality alerts based on specific criteria, defect recording, and facilitation of the CAPA process by directly connecting it to production and inventory orders.

- Product Lifecycle Management (PLM):

Odoo in the PLM application allows for the addition of engineering modifications to the product and improving its performance during the manufacturing stages to achieve the best quality for the final product. According to the application's inputs, you can specify the person responsible for the modifications and the date of the modifications, and then move them to the review stage.

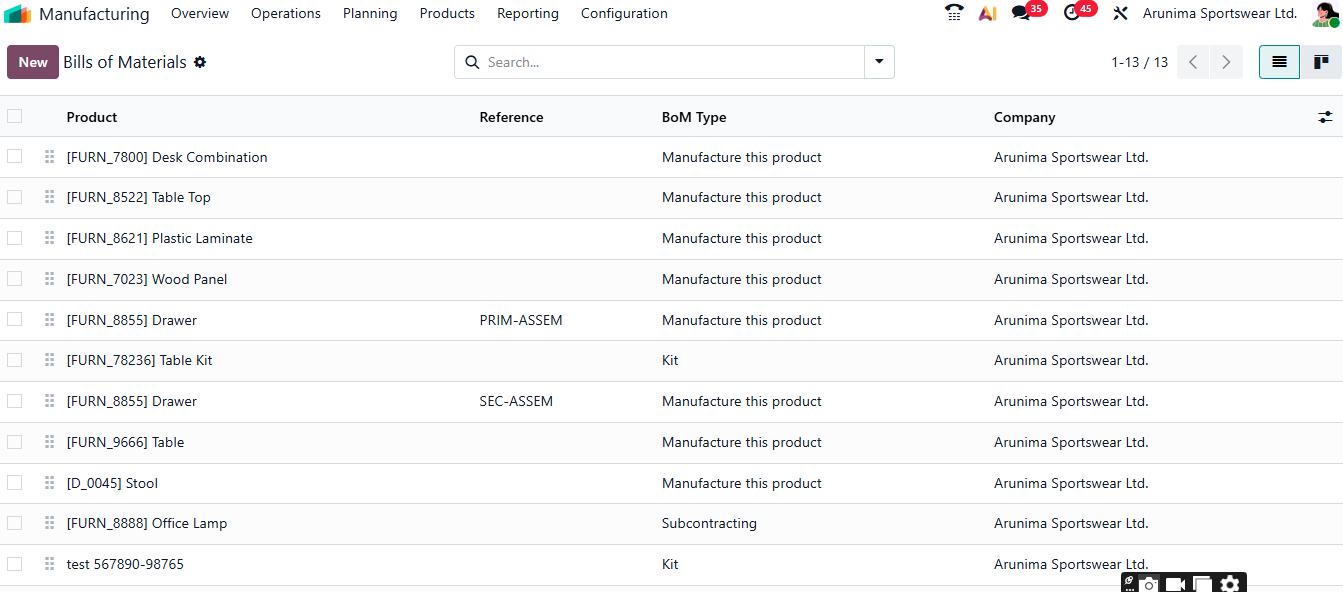

- BOM Product List:

Odoo provides the feature of using a unified Bill of Materials (BoM) across multiple product variants. Adopting a single Bill of Materials (BoM) for a product with variations achieves operational efficiency by eliminating the need to create and manage separate BoMs for each variation, significantly reducing administrative effort and time.

Second: Real-time reports for each level in manufacturing

The main reports this sector depends on several key areas: manufacturing order analysis, cost reports, operational performance reports, and labor performance measurement reports.

Manufacturing Order Analysis: A report on the quantities used in the manufacturing stages and the dates of the manufacturing orders to help monitor work progress and identify any delays or deviations from the schedule.

Cost reports: A detailed view of all costs associated with production (raw materials, labor, overhead), comparing them to the budget or standard costs to identify opportunities for cost savings.

Operational performance reports: Measure the efficiency and effectiveness of production processes and include metrics such as cycle time, defect rate and scrap identification, and equipment efficiency rate to identify bottlenecks and areas for improvement.

Labor performance measurement reports KPIs: Actual workforce report, where metrics such as standard time versus actual time for each task and absenteeism or turnover rates are monitored to assess training or hiring needs, and system integration with the HR application to monitor actual employee performance.

Finally:

Odoo ERP combines precise organization and real-time visibility across all operations and data on one platform, enabling companies to automate processes, reduce costs, achieve sustainable growth, and accelerate the production cycle.